Upstream Pressure Regulating Valves Series 700

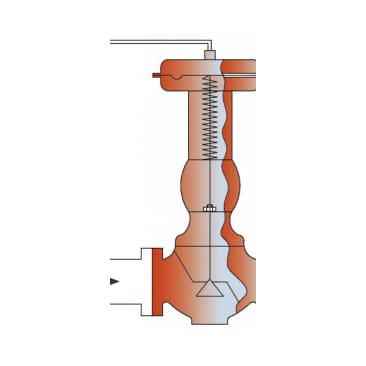

These are self operated upstream pressure regulating control valves, used in many applications for limiting pressure buildup (i.e. prevent overpressure) at its location in the pressure system.

Downloads

Specification DocumentDesign Features

- Glandless Construction: Where positive Zero gland packing is required the design scores over conventional solutions such as bellow seals etc. As the gland itself is eliminated.

- Wide range of body sizes to satisfy varied flow requirements

- Tight sensitivity and stability of controlled pressure.

- Provides excellent tight shutoff capability over long working life.

- Compact design with minimum number of moving parts.

- Simple resetting.

About Upstream Pressure Regulating Valves

These are self operated upstream pressure regulating control valves, used in many applications for limiting pressure buildup (i.e. prevent overpressure) at its location in the pressure system.

The valve opens in proportion to the inlet pressure preventing a rise of internal pressure in excess of a specified value.

These valves are used on a wide range of applications in the chemical process industry for up-stream pressure control, eg: Refineries, Fertiliser and Petrochemical Plants, Pharmaceutical and Food Processing Plants

-

What is an Upstream Pressure Regulating Control Valve?

An upstream pressure regulating control valve is a critical component in piping and fluid management systems, designed to regulate and maintain consistent upstream pressure in industrial processes. These control valves are essential for ensuring system stability, preventing overpressure conditions, and optimising performance across various applications. By controlling the pressure before it reaches downstream equipment, these valves help prevent damage, ensure safety, and enhance operational efficiency.

In industries where precise pressure control is necessary, the valve will automatically adjust to pressure variations, which ensures that processes continue running smoothly without disruptions caused by excessive fluctuations.

-

How Does an Upstream Pressure Regulating Valve Work?

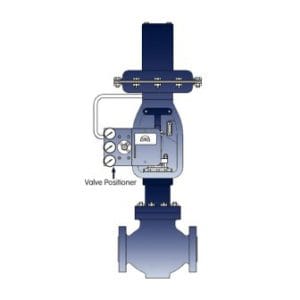

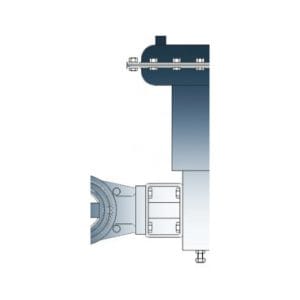

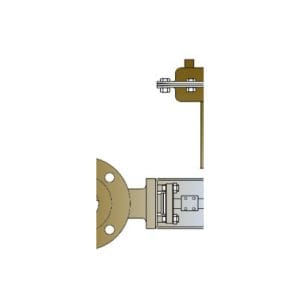

An upstream pressure regulating valve operates by automatically modulating the flow of fluid or gas, in response to upstream pressure changes. These valves can be classified as Pressure-Regulating Control Valves or Self-Acting Pressure Control Valves, depending on their design and function.

-

What are the Key Components of an Upstream Pressure Regulating Control Valve?

An upstream pressure regulating control valve consists of a valve body that houses components and manages the fluid flow, an actuator that opens and closes the valve based on pressure readings, and a pilot valve for enhanced accuracy. It also includes a diaphragm or piston that reacts to pressure fluctuations, a spring mechanism to maintain pressure settings, and a seat and plug to regulate the flow path, all working together to ensure consistent upstream pressure.

-

Industries Where Upstream Pressure Regulating Valves Are Commonly Used

Upstream pressure regulating control valves are widely utilised across numerous industries where pressure stability is crucial. Some of the most common sectors include:

Chemical Processing & Petrochemicals – Used in chemical plants and petrochemical refineries to maintain safe and consistent pressure levels in corrosive and high-pressure processes.

Oil & Gas Industry – Regulates pressure and prevents sudden pressure surges in gas processing plants, crude oil refining, and LNG facilities.

Pharmaceutical Manufacturing – Ensures precise pressure control in drug production processes, including filtration, sterilisation, and reactions.

Food & Beverage Processing – Maintains pressure in pipelines carrying liquid ingredients, steam, or gases to optimise hygiene, prevent contamination, and improve efficiency.

Power Generation – Used in steam and hydroelectric facilities to regulate pressure in various systems to ensure stable turbine operation.

-

Can These Valves Handle High-Pressure Applications?

Yes, upstream pressure regulating valves are designed to handle some high-pressure applications, care needs to be taken as they are limited based on the design constraints of the valve depending on the type required. They are available in various pressure ratings, typically ranging from ANSI 150 to ANSI 300, with higher ratings available upon request.

Product Specifications

| Design Code | ASM B16-34 |

| Valve Size | 15 to 600 mm (1/2” to 6”) |

| Valve Type | Direct Operated, Pilot Operated |

| Rating | ANSI 150 to 300 Higher on request |

| End Connection | Flanged up to 6”, Screwed up to 2” |

| Body Material | Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminium bronze |

| Trim Material | Stainless steel, Duplex stainless steel, 13% Chrome Steel, Monel Hastelloy B/C, Stellite |

| Diaphragm | Nitrile / Neoprene (nylon reinforced), Natural Rubber, EDPM, Viton, Teflon |

| Max. Temperature | As per the diaphragm limitations |