Self-Acting Pressure-Regulating Control Valves

Self-acting pressure-regulating valves can be considered for a wide range of applications and industries, from oil and gas to water supply systems. If you’re looking for a valve to automatically maintain a set pressure either upstream or downstream within a fluid system without requiring external power sources.

Showing all 2 resultsSorted by latest

-

Series 600

Series 600Downstream Pressure Regulating Valves

Downstream Pressure regulating valves are self contained, Self Operated control devices, which use energy from...

See Product -

Series 700

Series 700Upstream Pressure Regulating Valves

These are self operated upstream pressure regulating control valves, used in many applications for limiting...

See Product

-

What Are Self-Acting Pressure-Regulating Control Valves?

Self-acting pressure-regulating control valves are essential components in industrial piping systems, designed to automatically maintain a set pressure level without requiring an external power source or actuator. These valves are widely used in industries such as manufacturing, water treatment, HVAC, and chemical processing to ensure stable and efficient system performance.

A pressure-regulating control valve functions by adjusting the flow of a fluid (gas, steam, or liquid) in response to changes in system pressure. The term self-acting means that these control valves operate using the pressure energy from the process itself, eliminating the need for manual intervention or external power sources. This makes them an energy-efficient and reliable solution for pressure control in various industrial applications.

-

How Do Pressure-Regulating Valves Work?

Self-acting pressure-regulating control valves operate using a few key components:

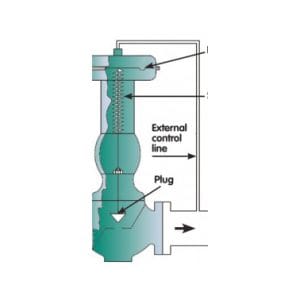

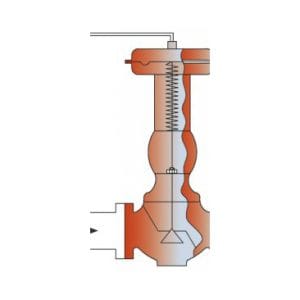

- Control Diaphragm or Piston – This senses pressure changes within the system and responds accordingly.

- Spring Mechanism – A pre-set spring force determines the pressure at which the valve will open or close.

- Valve Seat and Plug – These regulate fluid flow by adjusting their position based on pressure feedback.

- Sensing Line – Some designs include an external sensing line to monitor pressure at a specific point in the system.

When the system pressure increases beyond the desired level, the diaphragm or piston reacts to this change, prompting the valve plug to move and either restrict or release flow. Conversely, when pressure drops below the set point, the valve readjusts to allow more flow, maintaining consistent pressure throughout the system.

These valves are particularly advantageous in applications where precise pressure control is necessary but electrical or pneumatic actuation is not feasible.

-

What Happens When a Pressure Regulator Valve Fails?

A failure in a self-acting pressure control valve can lead to overpressure, flow disruption, leakage, and inconsistent system performance. If the valve fails in the closed position, excessive pressure can build up, risking damage to pipes and downstream components. Conversely, an open failure can cause insufficient pressure, leading to inefficiencies. Worn seals or diaphragm damage may result in leakage, increasing energy costs and environmental hazards.

Regular maintenance and inspections are essential to prevent failures. Routine checks on diaphragms, seals, and springs help identify wear before it leads to failure. Calibration ensures the valve responds correctly to pressure changes, and proper installation prevents mechanical stress. In some cases pressure relieving systems should be utilised to protect against self-acting regulator failure.

-

What Is the Difference Between Upstream and Downstream Control Valves?

Self-acting pressure control valves come in two main types: downstream and upstream pressure-regulating valves.

A downstream pressure-regulating valve maintains a constant pressure after the valve by adjusting flow accordingly, ensuring downstream equipment receives a consistent pressure regardless of fluctuations in the upstream supply.

An upstream pressure-regulating valve, or back-pressure regulator, controls the pressure before the valve by maintaining a specified setpoint. This prevents excessive pressure buildup in the supply system and ensures steady operation of upstream processes.

-

Why Choose High-Quality Self-Acting Pressure Control Valves?

When selecting industrial valves, it’s important to consider factors such as material compatibility, pressure range, and manufacturer reputation. At Valve Solutions we offer products designed to withstand demanding industrial conditions while providing consistent performance.