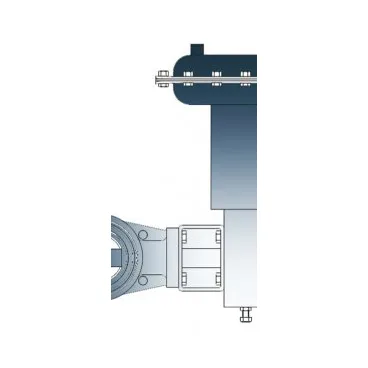

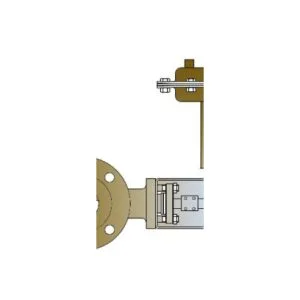

Butterfly Valves Series 200

Butterfly Valve design is the most common type of rotary valve and provides low weight to Cv Ratio combined with simplicity of design and comparatively low cost.

Downloads

Specification DocumentDesign Features

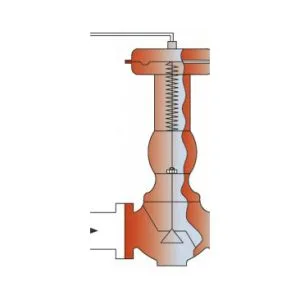

- Compact simple design low cost and maintenance free.

- High CV to Body size ratio.

- Reliable smooth operation and flow control.

- Bubble tight shut off, leakage Class VI.

- Rangeability of 33:1 in the control range

- Flow Characteristic throttling for modulating duty.

About Butterfly Valves

Butterfly Valve design is the most common type of rotary valve and provides low weight to Cv Ratio combined with simplicity of design and comparatively low cost.

It is a simple device to control or block the flow, a single vane or wafer disc pivots in the valve body. They can be found on a wide variety of applications for throttling or two position control in the chemical, paper and pulp, sugar industries, cooling water circulation, water treatment plants, compressed air, gas plant, flue gas desulphurisation plants etc.

Butterfly Valves have been around the industry for decades, performing well defined tasks and are Economic alternative to Gate valves, Ball valves, Plug valves etc...

Product Specifications

| Design Code | Wafer |

| Valve Size | 50 to 900 mm (2” to 36”) |

| Rating | 50 to 900mm (2" to 36") |

| Body Material | Cast Iron, Carbon Steel, Stainless Steel |

| Soft Seat | Teflon |

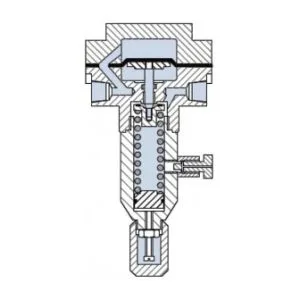

| Gland Packing | PTFE Chevrons, Graphite, Low emission |

| Actuator Form | Diaphragm, Piston, Electric |

| Actuator Type | Rotary |

| Diaphragm | Nitrile / Neoprene (nylon reinforced) |

| Spring Range | 3 – 15 Psig (0.2 – 1.0 Kg/cm2) 6 – 30 Psig (0.4 – 2.0 Kg/cm2) |

| Air Supply | 20 – 35 Psig (1.4 – 2.5 Kg/cm2) |

| Air Connection | 1/ 4” or 1/ 2” NPT |

| Accessories | Valve Positioners (Pneumatic, Electro-Pneumatic, Smart), Instruments (Airset, Solenoid Valve, Volume Booster, Airlock, Limit Switches) |

| Features | Top Mounted Hand Wheel, Side Mounted Hand Wheel, Limit Stops Removable Blind Head, Steam Jacketing, etc... |