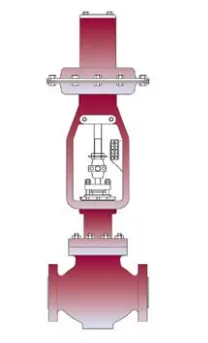

Globe Control Valves Series 110

This type of control valve with its globe body shape, uses the variable area generated within the control valve trim to control fluid flow.

Downloads

Specification DocumentDesign Features

- High flow capacity and rangeability.

- Large variety of trim designs.

- Top entry for ease of inspection and maintenance.

- Designed with clamped seat and trim configuration.

- Unbalanced or balanced plug design options to achieve specified leakage requirements

- Wide selection of actuators to meet most system requirements

About Globe Control Valves

This type of control valve with its globe body shape, uses the variable area generated within the control valve trim to control fluid flow.

Designed in accordance with ASME B16-34, it is single seated with unbalanced or balanced trim configurations and can be supplied with a wide variety of trim design options.

The valve can provide good positional accuracy, high rangeability and simplified maintenance.

It satisfies the majority of control applications throughout the process and power industries.

-

What Are Globe Control Valves?

Globe control valves are a type of industrial valve used to regulate fluid flow within piping systems. Unlike other valves, their unique spherical body houses a movable disc and stationary ring seat, enabling precise flow and pressure control.

As a trusted control valve manufacturer, we offer high-performance globe valves designed for durability, efficiency, and versatility across various industries.

-

How Does a Globe Control Valve Work?

A Control valve operates by moving a plug perpendicular to the seat, allowing for controlled flow modulation by increasing or decreasing the flow area. When the valve is open, fluid flows around the plug through the body; when closed, the plug seals against the seat, stopping flow entirely.

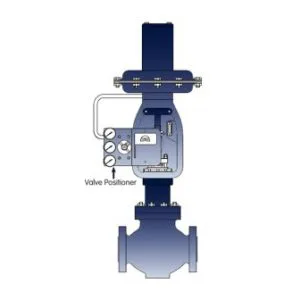

Actuation can be manual, pneumatic, hydraulic, or electric, depending on the application. This design provides excellent throttling capabilities, making globe control valves ideal for applications requiring precise flow adjustments.

-

Are Globe Control Valves Directional?

Yes, globe control valves are generally directional and must be installed correctly to ensure proper function. The flow direction is usually indicated by an arrow on the valve body, guiding fluid through the valve in a way that optimises pressure control and minimises wear. Incorrect installation can lead to reduced efficiency and increased maintenance requirements.

-

What Is the Difference Between a Gate Valve and a Globe Control Valve?

While both gate and globe control valves regulate flow, they function differently. Gate valves use a gate or wedge that moves up and down to start or stop the flow, but offers little control over the flow rate. In contrast, globe control valves enable precise flow regulation due to their throttling capability.

Additionally, gate valves are typically preferred for fully open or closed applications, whereas globe control valves excel in systems requiring intermediate flow control and constant modulation.

-

Can a Globe Control Valve Be Used for Throttling?

Yes, globe control valves are designed for throttling applications, unlike gate valves or general purpose globe valves, which are not suitable for regulating flow. The positioning of the plug within the valve body allows for gradual flow restriction, making them ideal for applications requiring precise adjustments. Industries such as water treatment, oil and gas, and chemical processing frequently use globe control valves for this reason.

-

Does a Globe Control Valve Reduce Pressure?

Globe control valves inherently cause a pressure drop due to their internal design geometry. As fluid passes through the valve, it changes direction multiple times, creating resistance that reduces pressure. The exact amount of pressure loss depends on factors such as valve size, flow rate, system pressure and trim design. Engineers must account for this when designing piping systems to ensure optimal performance.

-

What Can Flow Through a Globe Control Valve?

Globe control valves are versatile and can handle a wide range of liquids, gases and 2-phase flow. They are commonly used for controlling water, steam, oil, gas, air, and corrosive chemicals.

The choice of valve material, such as carbon steel, stainless steel, Aluminium Bronze or more exotic materials such as Duplex and Super Duplex, determines its compatibility with different substances. In high-pressure or high-temperature applications, selecting the right material ensures longevity and reliability.

Product Specifications

| Design Code | ASM B16-34 |

| Valve Size | 15 to 600 mm (1/2" to 24") |

| Rating | ANSI 150 to 2500 or equivalents to DIN, BS10, JIS etc... |

| End Connection | Flanged, Hubbed, Butt Weld, Screwed |

| Body Material | Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminium bronze |

| Bonnet | Standard up to 400°C, Normalising between 250°C to 500°C, Extended cold service -20°C to -100°C, Cryogenic -100°C to -250°C Bellowseal |

| Gland Packing | PTFE Chevrons, Graphite, Low Emission |

| Trim Form | Top Guided Contoured, Spline Micro Flow Ported Cage (unbalanced / balanced), Low Noise (LR1, LR2, LR3, LR4) |

| Trim Material | Stainless steel, Duplex stainless steel, 13% Chrome Steel, Monel Hastelloy B/C, Stellite |

| Flow Characteristic | Equal Percentage, Linear, Quick Opening |

| Seat Leakage | As per ANSI / FCI 70-2-2006 Class III, IV, V and VI |

| Actuator Form | Diaphragm, Piston, Electric |

| Actuator Type | Direct / Reverse Acting |

| Diaphragm | Nitrile / Neoprene (nylon reinforced) |

| Accessories | Valve Positioners (Pneumatic, Electro-Pneumatic, Smart), Instruments (Airset, Solenoid Valve, Volume Booster, Airlock, Limit Switches) |

| Features | Top Mounted Hand Wheel, Side Mounted Hand Wheel, Limit Stops Removable Blind Head, Steam Jacketing |