Downstream Pressure Regulating Valves Series 600

Downstream Pressure regulating valves are self contained, Self Operated control devices, which use energy from the controlled system to operate and regulate pressures.

Downloads

Specification DocumentDesign Features

- Reduces higher inlet pressure to a constant lower outlet pressure.

- Outlet pressure is accurate over a wide range of flows.

- Pilot operated, main valve is not subject to pressure fall off characteristic of direct-acting PRVs.

- Outlet pressure is adjustable over complete range of control spring.

- Range of body and diaphragm material combinations to meet the majority of requirements.

- Simple economic design.

- Operates automatically off line pressure.

- Heavy duty nylon reinforced diaphragm.

- Diaphragm assembly guided top and bottom.

- Throttling seat retainer for flow and pressure stability.

- Easily maintained without removal from the line.

- Pressure adjustment by single adjusting screw.

- Replaceable seat ring.

About Downstream Pressure Regulating Valves

Downstream Pressure regulating valves are self contained, Self Operated control devices, which use energy from the controlled system to operate and regulate pressures.

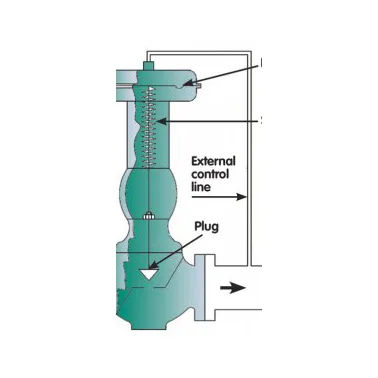

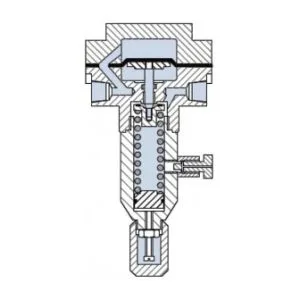

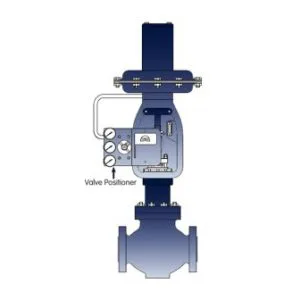

Valve Solutions manufactures a variety of pressure reducing regulators to manage downstream system pressures in low, medium, high flow applications, model features a diaphragm type, piston type or combination of both to suit different applications.

A pressure reducing regulator maintains a desired reduced outlet pressure while providing the required fluid flow to satisfy a variable downstream demand. The valve at which the reduced pressure is maintained is the outlet pressure setting of the regulator.

-

What is a Self-Acting Downstream Pressure Regulating Control Valve?

A Downstream Pressure Regulating Valve is a type of Pressure-Regulating Control Valve designed to control and maintain a stable pressure level downstream of the valve. By doing so, it prevents overpressure, ensuring that sensitive equipment and piping systems operate efficiently and safely.

These valves are widely used in various industries, including water treatment, oil and gas, chemical processing, and HVAC systems. As a self-acting pressure control valve, it functions autonomously, making real-time adjustments to compensate for fluctuations in supply pressure. This feature is particularly valuable in industrial applications where stable pressure control is critical to operational success.

-

What Controls the Downstream Pressure in a Regulator?

The downstream pressure in a regulator is controlled by a diaphragm, spring, and control orifice, which work together to adjust the valve opening in response to pressure fluctuations. The spring and diaphragm assembly ensures stability by opening the valve when pressure drops and closing it when pressure rises. An adjusting screw allows precise pressure setting adjustments, while advanced industrial valves may include a pilot-operated system for enhanced accuracy. These features enable control valves to maintain consistent pressure with minimal manual intervention.

-

What Sizes and Pressure Ratings Are Downstream Pressure Regulating Valves Available In?

Downstream Pressure Regulating Valves are available in sizes ranging from 15 mm to 200 mm (1/2″ to 8″) with pressure ratings from ANSI 150 to 300, and higher ratings upon request. Made from durable materials like stainless steel, ductile iron, and carbon steel, these valves ensure corrosion resistance and long-term performance across diverse industrial applications.

-

Are Downstream Pressure Regulating Valves Easy to Maintain?

Yes, these valves are designed for easy maintenance, requiring minimal downtime and reducing operational costs. Their inline maintenance capability allows servicing without removing the valve from the pipeline, while a replaceable seat ring ensures quick and cost-effective valve repairs. A single adjusting screw simplifies pressure modifications, and as a self-acting pressure control valve, it minimises manual intervention, making it a reliable, low-maintenance solution for industrial applications.

Product Specifications

| Design Code | ASM B16-34 |

| Valve Size | 15 to 600 mm (1/2" to 24") |

| Valve Type | Direct Operated, Pilot Operated |

| Rating | ANSI 150 to 300 Higher on request |

| End Connection | Flanged up to 6”, Screwed up to 2” |

| Body Material | Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminium bronze |

| Bonnet | Standard up to 400°C, Normalising between 250°C to 500°C, Extended cold service -20°C to -100°C |

| Gland Packing | PTFE Chevrons, Graphite, Low Emission |

| Trim Material | Stainless steel, Duplex stainless steel, 13% Chrome Steel, Monel Hastelloy B/C, Stellite |

| Seat Leakage | As per ANSI / FCI 70-2-2006 Class III, IV, V and VI |

| Diaphragm | Nitrile / Neoprene (nylon reinforced), Natural Rubber, EDPM, Viton, Teflon |