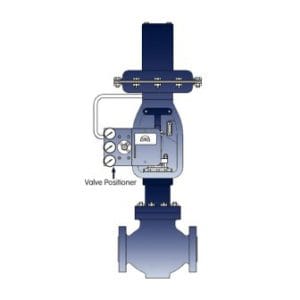

Angle Control Valves Series 170

The Series 170 Control Valve product range emulates the Series 110 design except that the valve body is an angle type constitution instead of a globe style.

Downloads

Specification DocumentDesign Features

- High flow capacity and rangeability.

- Large variety of trim designs.

- Top entry for ease of inspection and maintenance.

- Designed with clamped seat and trim configuration.

- Unbalanced or balanced plug design options to achieve specified leakage requirements

- Wide selection of actuators to meet most system requirements.

About Angle Control Valves

The Series 170 Control Valve product range emulates the Series 110 design except that the valve body is an angle type constitution instead of a globe style.

This range of control valves can be fitted with the same trim design options as the Series 110 product. It is used where the pipework configuration necessitates an angle pattern design.

The Series 170 can also be fitted with a selection of trim designs to suit each application in conjunction with the angle body configuration.

This range can be fitted with standard and severe service trim designs.

In conjunction with this the trims could be supplied manufactured in hard metal for potentially erosive applications.

-

What applications are Angle Control Valves typically used?

Angle Control Valves are utilised across multiple industries due to their ability to efficiently manage flow direction and control. They are particularly beneficial in scenarios where pipeline design requires a 90-degree turn, eliminating the need for additional fittings and reducing potential leak points. Industries that commonly employ Control Valves include:

- Oil and Gas Production

- Chemical Processing

- Power Generation

- Water Treatment

-

What can Angle Control Valves be made from?

To accommodate various fluids and operating conditions, Angle Control Valves are manufactured from a range of materials, each selected for its specific properties:

- Carbon Steel: Ideal for high-temperature and high-pressure applications, offering strength and durability.

- Chrome-Moly Steel: Provides enhanced resistance to corrosion and oxidation and is suitable for high-temperature services.

- Stainless Steel: Offers excellent corrosion resistance, making it suitable for a wide range of applications, including those involving corrosive fluids.

- Monel: A nickel-copper alloy known for its superior resistance to seawater and chemicals, ideal for marine and chemical processing applications.

- Alloy 20: Designed for applications involving sulfuric acid, this alloy offers exceptional corrosion resistance.

- Hastelloy B/C: Nickel-molybdenum alloys that provide excellent resistance to hydrochloric acid and other strongly reducing chemicals.

- Duplex Stainless Steel: Combines high strength with exceptional corrosion resistance, suitable for aggressive environments.

- Aluminium Bronze: Known for its high strength and resistance to corrosion, particularly in marine environments.

-

What actuators can be used with Angle Control Valves?

The performance of Angle Control Valves is significantly influenced by the type of actuator employed. Actuators facilitate the movement of the valve’s internal components, enabling precise control over fluid flow. Compatible actuators include:

- Diaphragm Actuators: Utilise air pressure to move the diaphragm, offering smooth and precise control, commonly used in low-pressure applications.

- Piston Actuators: Designed for high-pressure applications, these actuators provide greater force and are suitable for demanding environments.

- Electric Actuators: Offer precise control and are ideal for applications requiring automation and remote operation.

-

How does the top entry design affect the maintenance of the Angle Control Valve?

Angle Control Valves with a top-entry design provide significant maintenance advantages by allowing internal components to be accessed and serviced, without removing the valve from the pipeline. This design minimises operational interruptions by reducing downtime, as maintenance tasks can be performed more quickly.

-

Can these Angle valves handle severe service conditions?

Angle Control Valves are built for severe service conditions, including high pressures, extreme temperatures, and corrosion. Their durability comes from robust materials like Hastelloy and Duplex Stainless Steel, precision engineering, and specialised coatings such as Stellite for added wear resistance. These features ensure reliability and longevity in critical applications.

-

What are the available end connection types for Angle valves?

To ensure compatibility with various piping systems, Angle Control Valves are available with multiple end connection types, including:

- Flanged Ends: Provide a secure and leak-proof connection, facilitating easy installation and removal.

- Hubbed Ends: Offer a compact design suitable for high-pressure applications, ensuring a tight seal.

- Butt Weld Ends: Create a seamless connection, reducing potential leak points, and are ideal for high-pressure and high-temperature systems.

Product Specifications

| Design Code | ASM B16-34 |

| Valve Size | 25 to 600 mm (1” to 24”) |

| Rating | ANSI 150 to 2500 or equivalents to DIN, BS10, JIS etc... |

| End Connection | Flanged, Hubbed, Butt Weld |

| Body Material | Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminium bronze |

| Bonnet | Standard up to 400°C, Normalising between 250°C to 500°C, Extended cold service -20°C to -100°C, Cryogenic -100°C to -250°C Bellowseal |

| Gland Packing | PTFE Chevrons, Graphite, Low Emission |

| Trim Form | Top Guided Contoured, Spline Micro Flow Ported Cage (unbalanced / balanced), Low Noise (LR1, LR2, LR3, LR4) |

| Trim Material | Stainless steel, Duplex stainless steel, 13% Chrome Steel, Monel Hastelloy B/C, Stellite |

| Flow Characteristic | Equal Percentage, Linear, Quick Opening |

| Seat Leakage | As per ANSI / FCI 70-2-2006 Class III, IV, V and VI |

| Actuator Form | Diaphragm, Piston, Electric |

| Actuator Type | Direct / Reverse Acting |

| Diaphragm | Nitrile / Neoprene (nylon reinforced) |

| Accessories | Valve Positioners (Pneumatic, Electro-Pneumatic, Smart), Instruments (Airset, Solenoid Valve, Volume Booster, Airlock, Limit Switches) |

| Features | Top Mounted Hand Wheel, Side Mounted Hand Wheel, Limit Stops Removable Blind Head, Steam Jacketing |