Actuators Spring Opposed Diaphragms Series PD

Downloads

Specification DocumentDesign Features

- High power

- Fast response.

- Low stress components.

- Large variety of sizes.

- Easily serviceable.

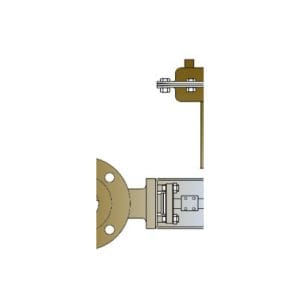

- Split coupling design for

- Attachment to valve.

- Wide range of accessories available.

About Actuators Spring Opposed Diaphragms

- High power

- Fast response.

- Low stress components.

- Large variety of sizes.

- Easily serviceable.

- Split coupling design for

- Attachment to valve.

- Wide range of accessories available.

-

What is a Diaphragm Actuator?

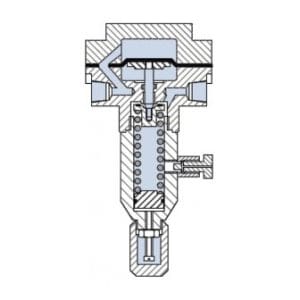

A diaphragm actuator is a mechanical device that converts pneumatic or hydraulic pressure into mechanical motion to control valves. It consists of a diaphragm, a spring, and a casing. When pressure is applied, the diaphragm flexes, operating the control valve. The spring diaphragm actuator is preferred for its precision, fail-safe operation, low maintenance, and consistent force output, making it ideal for applications that demand reliable and predictable valve movement in industrial process control.

-

What is the Difference Between a Piston Actuator and a Diaphragm Actuator?

Both piston actuators and diaphragm actuators serve the same purpose of controlling valves but they operate differently. Diaphragm actuators use a flexible diaphragm and spring, providing high precision, smoother control, and reliable force output. They are ideal for modulating control valves, though they respond slower than piston actuators.

On the other hand, piston actuators use a rigid piston with seals, delivering higher force output and faster response but with less precision. They are better suited for on/off applications and high-pressure systems. While piston actuators excel in high-force operations, diagram actuators offer smoother modulation and enhanced reliability in fine-tuned flow control applications.

-

What is the Difference Between Double-Acting and Spring Return Actuators?

Actuators are commonly classified into double-acting and spring return (also known as spring-opposed) types. Understanding these differences helps engineers choose the right option for their industrial valves.

Double-Acting Actuators: Require air pressure for both opening and closing the valve, providing precise bi-directional control. These actuators remain in their last position if power or air supply is lost. Unless fitted with a volume tank for fail-safe operation.

Spring Return Actuators (Spring Opposed Diaphragms): Use a spring to return the actuator to a predefined fail-safe position when air pressure is lost. This feature is essential for applications where safety and default valve positioning are critical.

-

What Happens if the Actuator Loses Power?

In most industrial systems, actuators rely on pneumatic pressure to function. If an actuator loses power (such as an air supply failure). A spring return diaphragm actuator will use its internal spring to default to a predetermined position (open or closed). If equipped with an airlock system, the actuator can retain air pressure, maintaining its position even after power loss.

An airlock device is particularly useful in situations where sudden valve movement could disrupt operations. By trapping air in the actuator chamber, the valve position remains unchanged until the air supply is restored.

-

How Much Instrument Air Pressure Can the Diaphragm Actuator Handle?

The instrument pressure handling capacity of Spring Opposed Diaphragm Actuators depends on their design and materials but is generally limited to the maximum working pressure of the diaphragm which should be regulated to within the following pressure range:

For Actuator sizes between 30 Square inch and 150 Square inch, up to 4 Barg

For larger Actuators of 300 Square inches or more this is limited to 3.5 Barg.

For applications requiring higher response speed or force output, a volume booster can be added. A volume booster increases the air supply volume, enabling faster actuator response times while maintaining precise control over the valve.

Product Specifications

| Actuator Type | Spring Opposed Diaphragm, Manual |

| Actuator Action | Direct / Reverse Acting |

| Diaphragm | Nitrile / Neoprene (nylon reinforced) |

| Spring Range | See Table 1 |

| Air Supply | 20 - 60 PsIG (1.4 - 4.0 Bar) |

| Air Connection | 1/4” or 1/2” NPT |

| Accessories | Valve Positioners - Pneumatic, Electro-Pneumatic, Smart |

| Instruments | Airset, Solenoid valve, Volume Booster, Airlock, Limit switches |

| Features | Top Mounted Handwheel, Side Mounted Handwheel, Limit Stops, Removable Blind Head, Steam Jacketing etc... |