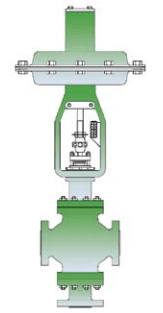

3 Way Globe Valves Series 130

Valve Solutions Three Way Globe control valves are used to combine two flows or to divert one flow into two outlets.

Downloads

Specification DocumentDesign Features

- High flow capacity and rangeability.

- Large variety of interchangeable trim sizes.

- Top entry for ease of inspection and maintenance.

- Wide selection of actuators to meet most system requirements.

About 3 Way Globe Valves

Valve Solutions Three Way Globe control valves are used to combine two flows or to divert one flow into two outlets.

They are designed to replace and perform the functions of two single ported control valves acting in opposite directions, in con- verging or diverging the flow.

They can be used to control the circulation of water, oil, sea water or other liquids, in heating or cooling applications involving heat exchange bypass control.

They can also be used in blending systems and on-off selector systems.

-

How Does a 3-Way Globe Valve Work?

A Three Way Globe Valve consists of three ports, allowing it to control the flow of fluids between multiple pipelines. These industrial valves function by diverting or combining flow based on system requirements. The key components of a Three Way Control Valve include:

- Valve Body – Houses the internal components and determines the valve’s capacity.

- Actuator – Controls the movement of the internal plug to regulate flow.

- Plug & Seat – The plug moves within the valve body to open, close, or partially obstruct flow, depending on the control signal.

- Stem – Connects the actuator to the plug, transmitting motion.

- Bonnet & Packing – Ensures a tight seal, preventing leaks and maintaining system integrity.

These components work together to modulate flow between the three ports. Depending on the valve configuration, a 3-way valve can be designed for mixing or diverting functions.

-

How Does a 3-Way Mixing Valve Work?

A Three Way Mixing Valve is designed to blend two separate fluid streams into a single, controlled output. This is commonly used in HVAC systems, chemical processing, and industrial heating applications.

A Three Way Mixing Valve operates by allowing two inlet ports to introduce different temperature or pressure fluids into the valve. The internal plug inside the valve modulates the flow, ensuring a precise mixture before the fluid exits through the third port at the desired temperature or pressure. This process enables accurate temperature control and fluid regulation within industrial systems.

By maintaining a consistent output, a Three Way Mixing Valve enhances efficiency and precision in various industrial processes. In temperature control, it ensures balanced heating and cooling by mixing hot and cold water. In chemical processing, it facilitates the proper blending of reactive substances before they enter production lines. Additionally, in industrial lubrication, it regulates oil temperature by mixing warm and cool lubricant streams to maintain optimal operating conditions.

-

How Does a 3-Way Diverting Valve Work?

A Three Way Diverting Valve functions by directing a single fluid stream into one of two different pipelines. Unlike a mixing valve, which combines flows, a diverting valve manages distribution between two distinct outputs.

A Three Way Diverting Valve operates as fluid enters through a single inlet port, where the internal plug moves within the valve body to regulate which outlet port receives flow. The fluid is then directed to the selected outlet based on control inputs or process requirements.

In HVAC systems, this control valve switches between different heating or cooling circuits based on demand. In industrial processes, it directs flow between alternate production lines or storage tanks. Additionally, in power plants, it regulate cooling water distribution to maintain operational efficiency. A Three Way Diverting Valve provides system flexibility by allowing operators to control fluid distribution dynamically, improving overall efficiency.

-

What Are the Three Types of 3-Way Globe Valves?

There are three main types of Three Way Globe Valves, each serving a specific function:

1. Three-Way Valve for Mixing

This type of valve is designed to combine two incoming flows into a single, regulated output, commonly used in temperature and pressure control applications to ensure a uniform output by adjusting the ratio of incoming fluids.

2. Three-Way Valve for Diverting

A diverting valve directs a single fluid source to one of two different output pathways, often used in industrial cooling systems to switch between heat exchangers, providing flexibility in fluid management by controlling the direction of flow.

3. Three-way valve with Pressure Balance Trim

This valve is specifically designed for high-pressure applications where fluid pressure differentials need to be managed. It reduces wear and tear on valve components by balancing forces within the valve body, increasing lifespan and reliability in demanding environments.

Product Specifications

| Design Code | ASM B16-34 |

| Valve Size | 15 to 300 mm (1/2” to 12”) |

| Rating | ANSI 150 to 600 or equivalents to DIN, BS10, JIS etc... |

| End Connection | Flanged, Butt Weld |

| Body Material | Carbon Steel, Chrome-moly Steel, Stainless Steel, Monel, Alloy 20, Hastelloy B/C, Duplex Stainless Steel, Aluminium bronze |

| Bonnet | Standard up to 400°C, Normalising between 250°C to 500°C, Extended cold service -20°C to -100°C, Cryogenic -100 ºC to -250 ºC Bellowseal |

| Gland Packing | PTFE Chevrons, Graphite, Low Emission |

| Trim Form | Skirt Guided, Linear, Pressure Balanced |

| Trim Material | Stainless steel, Duplex stainless steel, 13% Chrome Steel, Monel Hastelloy B/C, Stellite |

| Flow Characteristic | Linear |

| Seat Leakage | As per ANSI / FCI 70-2-2006 Class III, IV, V and VI |

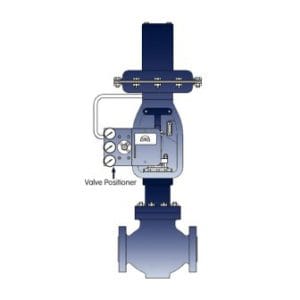

| Actuator Form | Diaphragm, Piston, Electric |

| Actuator Type | Direct / Reverse Acting, Direct Acting air failure “Close” top port, Reverse Acting air failure “Opens” top port. |

| Diaphragm | Nitrile / Neoprene (nylon reinforced) |

| Spring Range | 3-15 PSIG (0.2 - 1.0 Bar) 6-30 PSIG (0.4 - 2.0 Bar) |

| Air Supply | 20-60 PSIG (1.4 - 4.0 Bar) |

| Air Connection | 1/4” or 1/2” NPT |

| Accessories | Valve Positioners (Pneumatic, Electro-Pneumatic, Smart), Instruments (Airset, Solenoid Valve, Volume Booster, Airlock, Limit Switches) |

| Features | Top Mounted Hand Wheel, Side Mounted Hand Wheel, Limit Stops Removable Blind Head, Steam Jacketing |